Motor aging is a complex process that involves multiple components and factors, resulting in a variety of possible faults. The following are some common faults that may be caused by motor aging:

1、Performance degradation fault

①. Efficiency reduction:

·After the motor ages, its internal components such as windings and bearings may deteriorate, leading to a decrease in overall motor efficiency.

·Aging may lead to an increase in heat generation during motor operation, thereby reducing energy efficiency.

②. Increased heat generation:

·After the motor ages, the resistance of insulation materials and other components may increase, leading to an increase in heat generation during motor operation.

·Excessive temperature can accelerate the aging process of internal components of the motor, forming a vicious cycle.

③. Increase in operating current:

·Motor aging may lead to an increase in winding resistance, resulting in an increase in operating current.

·The increased current will further exacerbate the heating and aging of the motor.

2、Electrical faults

①. Insulation aging:

·The insulation material in the motor winding will be affected by various factors such as high temperature, humidity, voltage, and chemical corrosion during long-term use, resulting in a gradual decline in insulation performance.

·Insulation aging may cause electrical faults such as inter turn short circuits, phase loss operation, or motor rotor bar breakage.

②. Resistance increase:

·After the motor ages, the resistance of the windings and other electrical components may increase, leading to a decrease in motor performance.

③. Magnetic flux decrease:

·Electrical aging can affect the magnetic flux of a motor, which in turn affects its output power and efficiency.

3、Mechanical faults

①. Bearing overheating:

·Motor aging may lead to increased bearing wear, which in turn can cause bearing overheating.

·Overheated bearings may accelerate the aging process and even cause damage to the motor.

②. Excessive vibration:

·After the motor ages, the looseness and wear of mechanical components may cause excessive vibration problems.

·Excessive vibration not only affects the operational stability of the motor, but may also accelerate the aging of other components.

③. Abnormal sound:

·The aging of the motor may lead to increased friction and impact between mechanical components, which in turn can cause abnormal sound problems.

4、Environmental faults

①. Poor sealing:

·The aging of the motor may lead to the aging of the casing, which in turn can cause poor sealing.

·Poor sealing can make the motor susceptible to erosion from pollutants such as dust and oil, accelerating the aging process.

②. Corrosion and erosion:

·Dust, oil, salt, moisture, and other corrosive substances in the operating environment of the motor can corrode the insulation materials and other components of the motor.

·These substances can alter the structure and properties of insulation materials, leading to a decrease in insulation resistance and an increase in dielectric loss.

5、Other faults

①. Increased noise:

·Motor aging may lead to increased noise, which is usually caused by loose and worn mechanical components.

②. Shortened lifespan:

·Motor aging accelerates the wear and degradation process of its internal components, leading to a shortened lifespan of the motor.

In order to extend the service life of the motor and improve its operating efficiency, it is recommended to take the following measures:

·Regularly inspect the appearance of the motor, measure insulation resistance, lubricate and replace bearings, and perform maintenance work.

·Keep the operating environment of the motor clean and dry, and reduce the erosion of pollutants such as dust and oil.

·Strengthen heat dissipation measures, improve the heat dissipation efficiency of the motor, and avoid the occurrence of overheating.

In summary, the faults that may be caused by motor aging are diverse, and it is necessary to closely monitor its operating status and take effective measures to extend its service life and improve operating efficiency.

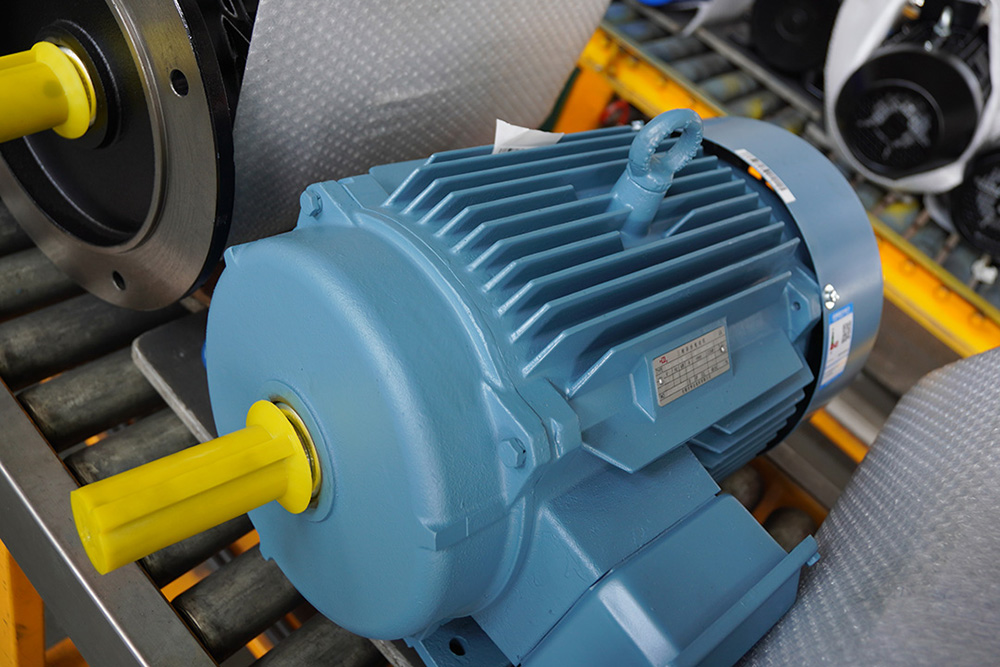

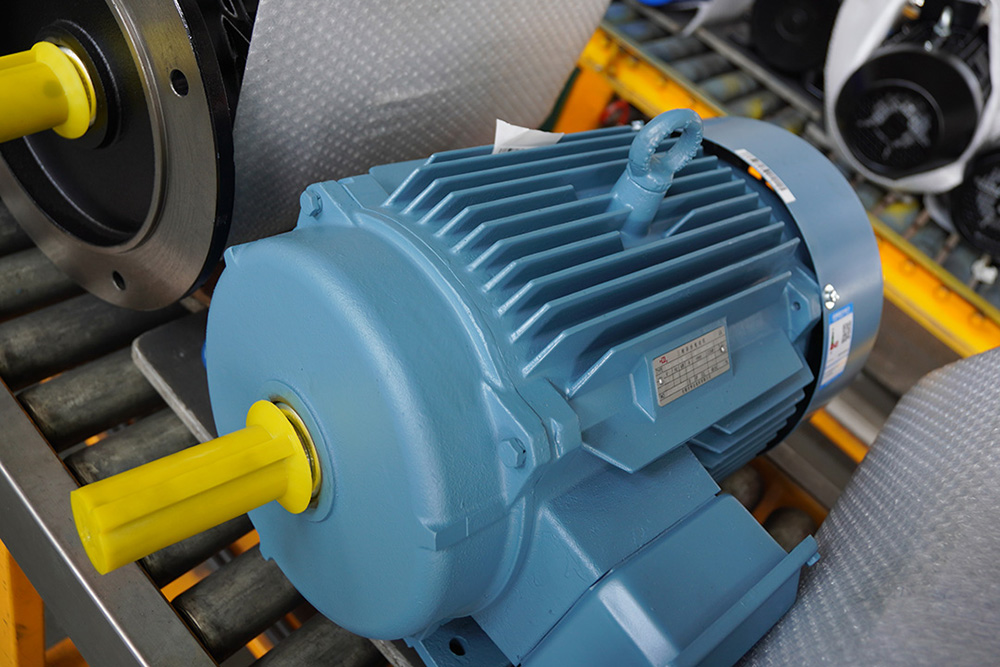

Hengda Electric has always been dedicated to the research and development, production, and service of various types of motors. With advanced technology and equipment, lean manufacturing processes, reliable product quality, and satisfactory after-sales service, the company provides customers with the most suitable motor professional solutions and creates greater social value.